INDUSTRIAL SHREDDERS

Industrial Shredders

UNTHA has accomplished its goal of being the preferred global brand with its more than 40 years of experience. With “reliability” as its core principle, UNTHA has manufactured solid and durable shredders.

Be it the shredding of bulky waste or turning industrial and household waste into secondary fuel, UNTHA shredding solutions provide reliable service.

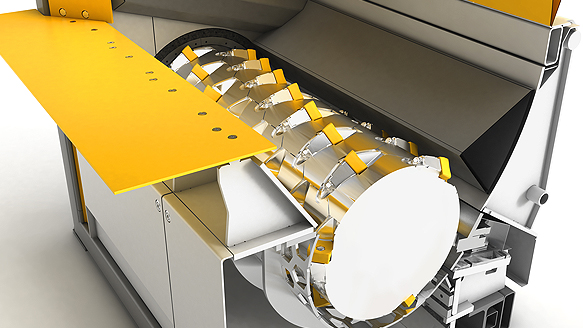

XR Series

During shredding, the output-controlled hydraulic ram device pushes the input material against the rotor equipped with indexable cutters. Once the material has been seized by the rotor, it is shredded against the stator blade. The screen bars are adjustable so that the final size of the shredded material can be determined according to requirement.

Applications

Industrial Waste

Bulky Waste

Waste Bales

Wood

Construction Waste

Hazardous Waste

Carpets and Rugs

TR Series

Thanks to the large diameter of the rotor and the specific geometry of the shredder casing, the rotor is able to pull in the material independently and the material is pressed against the cutting bars and shredded. The perforated screen determines the size of the final fragments.

Applications

Treated Household Waste

Treated Industrial Waste

Bales of Pre-Shredded Plastics

Pre-Shredded Plastic Film

Plastic Waste From Vehicle Dismantling

Pre-Shredded Waste From Plastics Industry

Packaging Materials